How to choose an Industrial Computer

2025-03-07

Industrial computers play a crucial role in automation, manufacturing, healthcare, energy, and other fields. They not only need to operate stably in high-intensity and highly complex environments but also meet diverse functional requirements. However, choosing a device suitable for one's application has become a challenge for many companies and engineers in the vast array of industrial computer products available in the market. IPCTECH, as a manufacturer of industrial computers, will provide you with a detailed analysis of the types of industrial computers, their application scenarios, and key factors to consider, helping you make informed decisions.

Industrial computers are primarily categorized into the following types based on their design and functionality:

Panel PC (Industrial Computer)

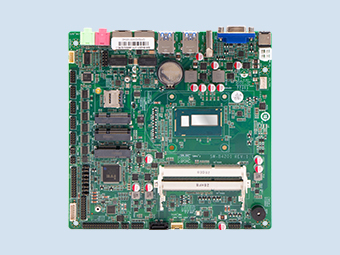

Panel PC is a device that integrates displays and hosts, suitable for light industrial applications. It features a rich array of input/output interfaces and expansion options to meet various peripheral connection needs. The Panel PC has screen sizes ranging from 8 inches to 24 inches and supports resistive touch screens or multi-touch functionality. Due to its high cost-effectiveness, Panel PC is an ideal choice for budget-constrained scenarios.

Touch Panel PC (Touchscreen Industrial Computer)

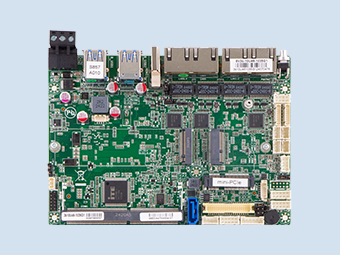

Touch Panel PC is designed to be lightweight and thin, suitable for standard industrial environments, typically fanless, and suitable for space-constrained applications. While Touch Panel PC has fewer I/O interfaces, its compact design gives it an advantage in specific scenarios.

Industrial Panel PC (industrial-grade panel computer)

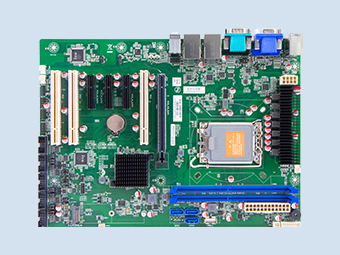

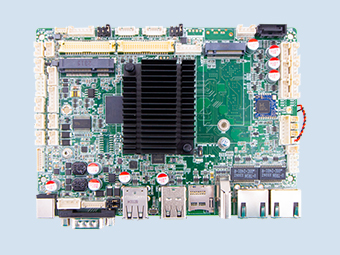

Industrial Panel PC is designed for heavy industrial environments, such as automotive manufacturing, dairy factories, and the petrochemical industry. It boasts strong scalability, supporting multiple drives, arrays, and rich I/O interfaces to meet high-intensity industrial requirements. Additionally, Industrial Panel PCs typically come with PCI/PCIE slots, supporting further hardware expansion.

The applications of industrial computers are very broad, virtually covering all fields that require high reliability and stability:

Industrial computers are often deployed in extreme environments, such as wind turbines in deserts and coastal areas, or outdoor energy and traffic monitoring systems. These environments are typically accompanied by significant day-night temperature differences, high humidity, and strong sandstorms, which ordinary computers struggle to handle.

In the fields of rail transit, autonomous vehicles, and aerospace, industrial computers need to withstand extreme vibrations and electromagnetic interference. For example, the control systems on high-speed trains must ensure stable operation at high speeds, while the computing units of autonomous vehicles need to process large amounts of data in real-time under complex road conditions.

In medical equipment and semiconductor factories, industrial computers must meet extremely high cleanliness requirements. For example, medical equipment in operating rooms needs to meet sterile standards, while cleanrooms in semiconductor factories require devices that can prevent tiny particles from contaminating silicon wafers.

As artificial intelligence technology advances, industrial computers are increasingly being applied in fields such as autonomous driving and intelligent manufacturing. For example, computational units in autonomous vehicles need to process sensor data in real time and make quick decisions, which places extremely high demands on the performance and reliability of computers.

When choosing an industrial computer, consider the following key factors comprehensively:

Industrial computers need to operate stably in extreme temperatures, humidity, dust, and other environments. For example, equipment in the oil and gas industry needs to withstand high temperatures, while outdoor equipment requires dust and waterproof features. Choosing equipment with a wide temperature operating range and high IP rating is crucial.

In remote sites that rely on generators or solar power, low-power industrial computers are ideal choices. Modern low-power devices can significantly reduce energy consumption and extend equipment operation time without sacrificing performance. IPCTECH's industrial computers employ low-power processor technology, ensuring high performance while reducing power consumption.

Protection class and military standards

IP ratings and MIL-STD standards are important indicators of industrial computer protection capabilities. The IP rating consists of two numbers: the first number indicates the dust protection rating, and the second number indicates the water resistance rating. For example, IP65 indicates that the device is completely dust-proof and can withstand impacts from low-pressure water flows. The MIL-STD standard ensures the reliability of equipment under extreme conditions such as vibration, impact, and humidity.

In military, maritime, and mobile applications, electromagnetic interference (EMI) may affect equipment performance. Choosing an industrial computer with EMI shielding can effectively prevent damage to the equipment from electromagnetic radiation. For example, some high-end industrial computers feature a Faraday cage design that shields against electromagnetic interference through conductive coatings or grids.

Industrial computers typically last 5 to 7 years, but their lifespan can be significantly extended through high-quality components and design. Choosing equipment with long-life chipset technology can reduce long-term maintenance costs and ensure high performance even after years of use.

IPCTECH is a company dedicated to the design, manufacture, and customization of industrial computers, known for its high quality and reliability.

Here are several reasons to choose IPCTECH:

IPCTECH offers comprehensive customization options from processors, storage, to connectivity and installation, ensuring that customers receive the solution that best meets their needs.

IPCTECH's team provides comprehensive professional guidance from selection to configuration, helping customers choose the most suitable equipment.

IPCTECH's industrial computers meet high standards and can operate stably in the most demanding environments, making them widely applicable in military, medical, energy, and manufacturing sectors to meet the needs of users across various fields.

When choosing an industrial computer, it is important to consider factors such as environmental adaptability, energy efficiency, protection rating, EMI shielding, and lifespan. IPCTECH can meet your specific needs with its customized solutions and high-quality products.

If you are looking for an industrial computer suitable for your application, please contact IPCTECH, which will provide you with professional support and services.

site: amodeipc.com

Types of Industrial Computers

Industrial computers are primarily categorized into the following types based on their design and functionality:

Panel PC (Industrial Computer)

Panel PC is a device that integrates displays and hosts, suitable for light industrial applications. It features a rich array of input/output interfaces and expansion options to meet various peripheral connection needs. The Panel PC has screen sizes ranging from 8 inches to 24 inches and supports resistive touch screens or multi-touch functionality. Due to its high cost-effectiveness, Panel PC is an ideal choice for budget-constrained scenarios.

Touch Panel PC (Touchscreen Industrial Computer)

Touch Panel PC is designed to be lightweight and thin, suitable for standard industrial environments, typically fanless, and suitable for space-constrained applications. While Touch Panel PC has fewer I/O interfaces, its compact design gives it an advantage in specific scenarios.

Industrial Panel PC (industrial-grade panel computer)

Industrial Panel PC is designed for heavy industrial environments, such as automotive manufacturing, dairy factories, and the petrochemical industry. It boasts strong scalability, supporting multiple drives, arrays, and rich I/O interfaces to meet high-intensity industrial requirements. Additionally, Industrial Panel PCs typically come with PCI/PCIE slots, supporting further hardware expansion.

Applications of Industrial Cmputers

The applications of industrial computers are very broad, virtually covering all fields that require high reliability and stability:

Extreme environments

Industrial computers are often deployed in extreme environments, such as wind turbines in deserts and coastal areas, or outdoor energy and traffic monitoring systems. These environments are typically accompanied by significant day-night temperature differences, high humidity, and strong sandstorms, which ordinary computers struggle to handle.

High-vibration and high-electromagnetic interference environments

In the fields of rail transit, autonomous vehicles, and aerospace, industrial computers need to withstand extreme vibrations and electromagnetic interference. For example, the control systems on high-speed trains must ensure stable operation at high speeds, while the computing units of autonomous vehicles need to process large amounts of data in real-time under complex road conditions.

Environment with high cleanliness requirements

In medical equipment and semiconductor factories, industrial computers must meet extremely high cleanliness requirements. For example, medical equipment in operating rooms needs to meet sterile standards, while cleanrooms in semiconductor factories require devices that can prevent tiny particles from contaminating silicon wafers.

AI-driven applications

As artificial intelligence technology advances, industrial computers are increasingly being applied in fields such as autonomous driving and intelligent manufacturing. For example, computational units in autonomous vehicles need to process sensor data in real time and make quick decisions, which places extremely high demands on the performance and reliability of computers.

Key Factors for Choosing Industrial Computers

When choosing an industrial computer, consider the following key factors comprehensively:

Environmental adaptability

Industrial computers need to operate stably in extreme temperatures, humidity, dust, and other environments. For example, equipment in the oil and gas industry needs to withstand high temperatures, while outdoor equipment requires dust and waterproof features. Choosing equipment with a wide temperature operating range and high IP rating is crucial.

Energy efficiency design

In remote sites that rely on generators or solar power, low-power industrial computers are ideal choices. Modern low-power devices can significantly reduce energy consumption and extend equipment operation time without sacrificing performance. IPCTECH's industrial computers employ low-power processor technology, ensuring high performance while reducing power consumption.

Protection class and military standards

IP ratings and MIL-STD standards are important indicators of industrial computer protection capabilities. The IP rating consists of two numbers: the first number indicates the dust protection rating, and the second number indicates the water resistance rating. For example, IP65 indicates that the device is completely dust-proof and can withstand impacts from low-pressure water flows. The MIL-STD standard ensures the reliability of equipment under extreme conditions such as vibration, impact, and humidity.

EMI shielding

In military, maritime, and mobile applications, electromagnetic interference (EMI) may affect equipment performance. Choosing an industrial computer with EMI shielding can effectively prevent damage to the equipment from electromagnetic radiation. For example, some high-end industrial computers feature a Faraday cage design that shields against electromagnetic interference through conductive coatings or grids.

Lifespan and Reliability

Industrial computers typically last 5 to 7 years, but their lifespan can be significantly extended through high-quality components and design. Choosing equipment with long-life chipset technology can reduce long-term maintenance costs and ensure high performance even after years of use.

Why choose IPCTECH?

IPCTECH is a company dedicated to the design, manufacture, and customization of industrial computers, known for its high quality and reliability.

Here are several reasons to choose IPCTECH:

Customized services

IPCTECH offers comprehensive customization options from processors, storage, to connectivity and installation, ensuring that customers receive the solution that best meets their needs.

Expert Support

IPCTECH's team provides comprehensive professional guidance from selection to configuration, helping customers choose the most suitable equipment.

High quality and reliability

IPCTECH's industrial computers meet high standards and can operate stably in the most demanding environments, making them widely applicable in military, medical, energy, and manufacturing sectors to meet the needs of users across various fields.

Conclusion

When choosing an industrial computer, it is important to consider factors such as environmental adaptability, energy efficiency, protection rating, EMI shielding, and lifespan. IPCTECH can meet your specific needs with its customized solutions and high-quality products.

If you are looking for an industrial computer suitable for your application, please contact IPCTECH, which will provide you with professional support and services.

Get Price:

Cal: +8615538096332site: amodeipc.com

Recommended