What is the difference between IPC and PC

2025-02-26

What is the difference between IPC and PC?

In today's digital age, computers have become indispensable tools in all fields. However, in different application scenarios, the performance, stability and adaptability of computers have very different requirements. Industrial computers (IPCs) and personal computers (PCs) are two types of computing devices that are adapted to different environments, and there are many significant differences between them.Definition of foundations: computational tools in their own right

Personal computers (PCs): a powerful assistant in daily work and life

A personal computer is a general-purpose computing device designed to meet the needs of an individual or business for everyday use. In our daily life and office scenarios, it is everywhere. Whether it's opening a browser to browse news and information, using office software for document editing, or playing some relaxing games in our leisure time, PCs are able to fulfill their tasks with excellence. It is designed around the concept of user-friendly operation and broad application compatibility, and strives to provide users with a rich and diverse functional experience.

Industrial PCs (IPCs): the heroes behind the scenes in industry

Unlike PCs, industrial computers are built for industrial environments. Industrial PCs play a critical role on factory floors, oil rigs, logistics and transportation hubs, and more. They are specially designed to withstand extreme temperature variations, strong mechanical vibrations, and high levels of dust contamination. In industrial automated production lines, industrial computers are responsible for controlling the operation of various mechanical equipment and realizing the precise automation of production processes; in the oil and gas extraction industry, it monitors and manages complex drilling operations in real time; in the field of transportation, industrial computers ensure the efficient and stable operation of logistics and fleet management systems.

Hardware differences: different options for different scenarios

PCs: the quest for performance-cost balance

Standard PCs often utilize consumer-grade hardware components that are designed to deliver powerful computing performance at a reasonable cost. For example, a high-performance processor allows users to multitask and run large pieces of software more smoothly; plenty of RAM allows multiple applications to be open at the same time; and fast storage greatly reduces the time it takes to read and write files and meets users' needs for things like game loading speeds. However, these components are often not specially hardened for harsh environments and are prone to failure in environments with high temperatures, high humidity, dusty conditions, or intense vibration.

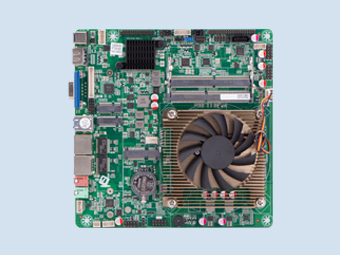

IPC: built for harsh environments

The industrial computer is built with industrial-grade hardware components for superior durability and stability. Its chassis is made of sturdy materials that can effectively withstand external collisions and impacts. In order to cope with the heat dissipation challenges in industrial environments, some industrial computers adopt a fanless design, which distributes heat evenly through a special cooling structure, avoiding overheating problems caused by fan failure and reducing the risk of dust entering the interior of the device. Their internal components are specially reinforced to maintain stable operation under strong vibration and shock. In addition, the industrial PCs are equipped with a series of interfaces dedicated to industrial applications, such as RS-232 serial ports, which are essential for connecting industrial equipment, enabling data transfer and control commands.

Software and operating systems: functional support with a different focus

PC operating systems: focus on user experience and application diversity

Commonly used operating systems for personal computers such as Windows 10 and macOS are known for their user-friendly interfaces and rich ecosystem of applications. These operating systems provide an intuitive graphical user interface that allows even computer novices to get started quickly. At the same time, they support a huge number of software applications covering various fields such as office, entertainment, learning, design, etc., which fulfill the diversified needs of users.

IPC operating system: emphasizing stability and real-time performance

The operating systems used in industrial computers are significantly different from PCs. The common ones are Windows IoT, real-time operating systems (RTOS), and customized Linux distributions. These operating systems prioritize stability, security, and real-time performance because in industrial production, any system failure or delay can lead to serious production accidents and economic losses. For example, in an automated production line, an industrial computer needs to collect and process various sensor data in real time, and issue control commands in a timely manner to ensure the accuracy of the production process. In addition, the software on industrial computers is usually custom-developed for specific industrial tasks, focusing on achieving production process control, data acquisition and analysis, equipment condition monitoring and other functions. In order to improve the efficiency of operation and maintenance, many industrial computer software also has remote management and diagnostic functions, technicians can remotely monitor and maintain the equipment through the network, timely detection and resolution of potential problems, to minimize equipment downtime.

Environmental resistance: a key factor in determining application scenarios

Temperature resistance: adapted to extreme working environments

Industrial computers have excellent temperature adaptability and can operate in very high or very low temperatures. In the heat of summer, temperatures on the factory floor can reach 40 degrees Celsius or higher, while in cold warehouses or outdoor industrial facilities, temperatures can drop to minus ten degrees Celsius. Industrial PCs ensure stable operation in these extreme temperatures through optimized thermal design and electronic components that are resistant to high and low temperatures. In contrast, ordinary PCs are prone to crashing and rebooting when the temperature is too high, and in low temperatures, they may face battery performance degradation and hardware startup difficulties.

Dust and moisture protection: a robust line of defense to protect internal components

Dust and moisture are ubiquitous in industrial production environments. In order to resist the erosion of these harmful substances, industrial computers adopt sealed-designed chassis, which effectively prevents dust and liquids from entering the interior of the device and protects the fragile electronic components. For example, in dusty industries such as coal mining and cement production, the sealed protection of industrial PCs ensures stable operation for long periods of time in harsh dusty environments. The chassis of ordinary PCs usually does not have such strict sealing measures, and once too much dust accumulates, it may lead to poor heat dissipation, short circuits and other malfunctions; in humid environments, it is also prone to hardware corrosion, shortening the service life of the equipment.

Vibration and shock resistance: adapting to the vibration environment of industrial equipment

Industrial production processes are often accompanied by vibrations and shocks from various mechanical equipment. With special fixing methods and reinforcement designs, industrial computers enable their internal components to be firmly fixed in the chassis and remain in normal working condition even under long periods of strong vibration and frequent shocks. For example, in environments such as production lines of automobile manufacturing plants and construction sites, industrial PCs can operate stably and provide reliable support for equipment control and data acquisition. In contrast, when ordinary PCs are subjected to slight vibration or shock, it may lead to problems such as hard disk damage, loose parts, etc., affecting normal use.

Other comparisons: showing differences in all directions

Design and construction: different approaches to robustness and convenience

The design of industrial computers is centered on ruggedness and durability, and their housings are usually made of high-strength metal materials, and their internal structures are carefully designed to effectively disperse and absorb external impacts. This rugged design enables them to operate stably for long periods of time in harsh industrial environments, reducing the number of equipment failures and repairs. In contrast, ordinary PCs focus more on the thin and light appearance and ease of use, and their shell material and internal structure are relatively fragile, making it difficult to withstand the various tests in industrial environments. If ordinary PCs are used in industrial environments, they often need to be equipped with additional protective enclosures and other safety facilities, which not only increases the cost, but also increases the size of the equipment and takes up more space.

Electromagnetic and radio-frequency interference protection: safeguarding the stability of data transmission

In industrial environments, there are a large number of sources of electromagnetic interference and radio frequency signals, such as large motors, transformers, and wireless communication equipment. These interferences may have a serious impact on the data transmission and processing of the computer, resulting in data loss, errors or system failures. By adopting special shielding materials and circuit design, industrial PCs are equipped with strong resistance to EMI and RFI to ensure the accuracy and stability of data transmission in complex electromagnetic environments. While ordinary PCs are relatively weak in this aspect of the protection ability, in a strong electromagnetic interference environment, there may be unstable network connection, data transmission errors and other problems.

Levels of protection: clear identification of protection capabilities

Protection Rating (IP Rating) is an important indicator of how well a device is protected against dust, water, etc. Industrial computers typically have a high IP rating, such as the common IP65 rating, meaning that they are completely protected from dust and can withstand water spray from all directions without damage. This high level of protection ensures that industrial PCs can operate in harsh industrial environments. In contrast, ordinary PCs have lower IP ratings and are generally only able to meet the basic protection needs of everyday office environments.

Maintenance and replacement costs: economic considerations for long-term use

In terms of long-term cost of ownership, industrial computers offer some advantages in terms of repair and replacement hardware. Although the initial purchase cost of industrial computers may be higher, the quality of the industrial-grade components used is reliable and the failure rate is relatively low. Moreover, because the design of industrial PCs focuses on modularity and easy maintenance, once a hardware failure occurs, it is relatively easy to repair and replace parts, and the cost is relatively controllable. In contrast, although the purchase cost of ordinary PCs is lower, but in the industrial environment is prone to failure, and because most of its components are consumer-grade products, the probability of damage in harsh environments is higher, the cost of repair and replacement may increase with the increase in the use of time and continue to rise.

Hardware scalability: adapting to technological developments

As technology continues to advance, the need for upgrading and expanding computer hardware is increasing. Industrial computers are designed with this in mind and have good hardware expandability. It is usually reserved for a number of slots and interfaces to facilitate the user according to the actual needs of adding or replacing hardware components, such as increasing memory, expanding storage capacity, upgrading the processor and so on. This flexibility allows industrial computers to better adapt to the changing needs of industrial production. Although ordinary PCs also have a certain degree of hardware expandability, in the industrial environment, due to its structure and design limitations, the expansion of hardware may face many difficulties, such as lack of space, compatibility issues.

Summing up: each to his own, as appropriate

Industrial computers and personal computers are significantly different in terms of definition, hardware, software, environmental resistance, and several other aspects. With its powerful versatility, rich software resources and friendly user experience, personal computers have become the tool of choice for people's daily life and office work; while industrial computers play an irreplaceable role in industrial production, energy extraction, transportation and other fields due to their excellent stability, reliability and high adaptability to harsh environments.

With the rapid development of Industry 4.0 and intelligent manufacturing, the demand for industrial computers will continue to grow. Its importance in improving industrial production efficiency, ensuring production safety, and realizing automation and intelligent control is becoming increasingly prominent. At the same time, with the continuous progress of technology, industrial computers will also continue to innovate and upgrade, providing stronger support for the development of the industrial sector. In the future, we can expect industrial computers to play a greater role in more areas, to promote the digital transformation and intelligent development of various industries.

Recommended