What is the Use of Industrial Panel PC?

2025-02-28

Introduction

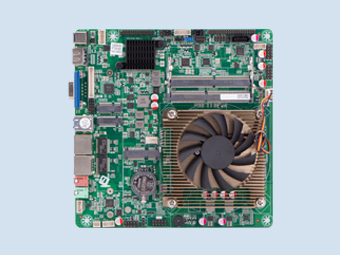

With the rapid development of industrial automation, Industrial Panel PCs (IPCs) are gradually becoming an indispensable tool in modern industrial environments. They are widely used in factories, warehouses, control rooms and other scenarios with their rugged design, efficient performance and flexible integration capabilities.What is Industrial Panel PC?

An industrial tablet PC is an all-in-one device with an integrated display screen and computing capabilities, usually equipped with a touchscreen, for environments that require intuitive operation. Compared to traditional desktop computers, industrial tablets are more compact, durable, and able to withstand harsh industrial environments such as high and low temperatures, vibration, dust, and humidity.Also known as industrial computers or ruggedized computers, industrial tablet PCs are designed to meet the high reliability and performance demands of industrial applications. They are not only the core devices for data processing, but also assume an important role in human-machine interaction (HMI).

Key Features of Industrial Panel PCs

The reason why industrial panel PCs can stand out in industrial environments is due to their unique design and features. The following are its core features:Ruggedized Design

Industrial Panel PCs are usually made of aluminum alloy or stainless steel, which is waterproof, dustproof and corrosion-resistant (compliant with IP protection rating). This design enables it to operate stably in harsh environments such as factories and outdoors.Touch Screen Technology

Equipped with capacitive or resistive touch screen, it supports gloved operation, which is convenient for industrial personnel to operate intuitively in complex environments.Wide temperature operating range

Whether it's a cold warehouse or a hot factory, the industrial Panel PC can maintain stable performance under extreme temperatures.Customizable Configuration

Users can choose the screen size, processor configuration, I/O interface type, and mounting method (e.g., wall or panel mount) according to their needs.Fanless Design

The fanless structure reduces the risk of mechanical failure while realizing silent operation and efficient heat dissipation.Powerful Connectivity

Equipped with a variety of interfaces (e.g. USB, RS232, etc.), it can be easily integrated into existing devices and systems.Why Industrial Panel PCs Matter?

Designed for industrial environments, Industrial Panel PCs offer the following advantages:Seamless integration

Industrial Panel PCs can be easily installed into equipment such as control cabinets, machines or operator consoles, and integrate seamlessly into existing production line architectures.Human Machine Interaction (HMI)

As a human-machine interface, industrial tablet PCs provide operators with intuitive control via a touch screen, ensuring efficient and safe equipment operation.High Durability

Its robust design can withstand harsh conditions such as vibration, shock, dust and humidity to ensure long-term stable operation.Space-saving

The all-in-one compact design saves valuable space and is especially suitable for industrial environments where space is limited.Common Applications of Industrial Panel PCs

Industrial panel PCs play an important role in many industries, and the following are their main application scenarios:Manufacturing and Process Control

In manufacturing environments, industrial tablet PCs are used to monitor and control production lines in real time, supporting processes such as assembly, quality inspection and packaging. Its touchscreen interface makes operation more intuitive and reduces downtime.Human Machine Interaction (HMI)

As the core device for human-machine interaction, industrial tablet PCs realize seamless communication between operators and machines through the touch screen to ensure efficient operation of the equipment.Data Visualization and Analysis

Equipped with high-performance processors and high-resolution displays, industrial tablet PCs are able to clearly display and analyze a large amount of data, which is especially suitable for energy, transportation and other industries that require real-time monitoring.Transportation and Logistics

In the field of transportation and logistics, industrial tablets are used for fleet management, route optimization and cargo tracking. Their rugged design ensures reliability in complex environments such as vehicles and warehouses.Oil & Gas

In the oil and gas industry, industrial tablets are used to monitor and control critical equipment such as drilling, pipelines and refineries, and their high temperature and corrosion resistance make them ideal.Food and Beverage Processing

Industrial tablets are used in the food and beverage industry to automate production and quality control, such as regulating temperature and humidity in storage environments or monitoring production lines.Water Treatment and Utilities

In water treatment plants and utilities, industrial tablets are used to monitor water quality, control treatment processes and ensure efficient distribution of water resources.How to choose the right Industrial Panel PC?

When selecting an Industrial Panel PC, the following factors need to be considered:

Environmental suitability

Depending on the environment in which it will be used, choose a device that meets the IP protection rating to ensure that it is resistant to water, dust and other contaminants.Performance Requirements

Select the appropriate processor and memory configuration according to the application scenario to ensure that the device can meet the computing and data processing requirements.Connectivity

Ensure the appliance is equipped with the required I/O interfaces for seamless integration with existing systems.Customization options

Select a model that supports customization to meet specific application requirements.Industrial Panel PCs for your Industry

Industrial Panel PCs not only enhance current productivity, but also set the stage for future growth:

Invest in the future

With powerful connectivity and intelligent performance, industrial tablets can adapt to rapidly changing environments and provide businesses with a competitive edge.Enhance Automation

As the core equipment of industrial automation, industrial tablet PCs realize efficient collaboration between people and machines and promote the intelligence of production processes.Adapt to multiple environments

The rugged design and versatility of industrial tablet PCs enable them to adapt to a variety of industrial environments, ensuring safe and reliable operations.Future Trends in Industrial Panel PCs

With the continuous advancement of technology, industrial tablet PCs are developing in the direction of being smarter and more efficient:

Internet of Things (IoT) Integration

Industrial Tablet PCs will become the core hub of IoT devices, enabling smarter industrial operations.Artificial Intelligence (AI) Applications

With enhanced processing power, industrial tablets will support AI-driven predictive maintenance and data analytics.5G Connectivity

High-speed internet will enable real-time data sharing and remote monitoring to further enhance industrial efficiency.Sustainability

Future industrial tablet PCs will pay more attention to energy efficiency and environmentally friendly design to meet the needs of green manufacturing.Conclusion

With its robust design, efficient performance and wide range of application scenarios, industrial tablet PCs have become an important part of modern industrial automation. Whether it is to enhance productivity, realize intelligent operation, or adapt to future technology trends, industrial tablet PCs provide powerful support for enterprises.Call to action

If you are looking for a reliable industrial tablet PC solution, please feel free to contact IPCTECH. we offer a wide range of customization options to meet your specific needs.Tel: 8615538096332

Email: arvin@ipctech.com.cn

Recommended